Everything You Need to Know About Traffic Cone

This article is written for engineers, students majoring in engineering, procurement personnel, and enthusiasts involved in traffic construction, road construction, and construction in work areas. As a frontline traffic cones manufacturer, we aim to provide you with some professional knowledge about traffic cones, enabling you to have a deeper understanding and appreciation of them.

What Is the Traffic Cone?

Traffic cone, also called road cone, parking cone, safety cone, caution cone, or construction cone, is a conical object primarily used for marking traffic, road, and parking, it’s mainly composed of plastic or rubber, with flexibility, visibility, and portability.

History of Traffic Cone

Do you know the history of traffic cones? The invention of traffic cones is quite interesting. A US painter named Charles D. Scanlon invented the traffic cone. What led him to invent it? The painter, Charles D. Scanlon, often painted wooden barricades on the streets of Los Angeles. However, shortly after painting, the barricades would deteriorate under the sun and rain. He had to repaint them continuously, which he found troublesome. So, he had a bright idea: why not turn the barricades into cone shapes and use rubber material instead? This way, he could increase their lifespan. And thus, his idea was realized.

What Material Are Traffic Cones Made Of?

Traffic cones are divided into three types: PE Traffic cone, PVC traffic cone, and rubber traffic cone.

PE cones are composed of a cone body made of PE material and a rubber base, with the cone being produced using blow molding technology.

PVC cones are made up of a cone formed by PVC injection molding and an injection-molded rubber-plastic base.

Rubber cones are made of recycled rubber and produced through a process of extruding rubber molds.

What Colour Are Traffic Cones? What’s the Meaning of Cone Colour?

-

Orange Cones - Warning, indicates there is an unknown danger ahead, please take more attention and drive slowly.

- Lime Green Cones - Safety Equipment, as per OSHA, Green is recognized to first-aid stations for placing emergency equipment and used for some events.

- White Cones - Safe, this access is safe for pedestrians and workers to pass.

- Blue Cones - Notice, safety ahead, just take a look for everything.

- Yellow Cones - Caution,be aware of potential hazards or dangers ahead of the road when you are walking or driving.

- Red Cones - Danger, indicates there is a danger ahead with injury or death by an accident.

- Pink Cone - Commercial, it's widely used in commercial streets, with some advertisements on the cone body.

Traffic Cone Size

Different standards have different sizes, below are some standard sizes for several countries..

US Standard MUTCD Regulations traffic cone sizes:

12 inches (30 cm), 1.5 lb (0.68 kgs) , application for indoor and outdoor

18 inches (45 cm), 3 lb (1.4 kgs), for outdoor applications including traffic and safety management

28 inches (70 cm), 7 lb (3.2 kgs), used for traffic safety in streets

28 inches (70 cm), 10 lb (4.5 kgs), used for freeway and highway applications with reflective collars

36 inches (90 cm), 10 lb (4.5 kgs), used for freeway and highway applications with reflective collar

In New Zealand, only 2 sizes of traffic cones used on the road:

18 inches (45 cm), 1 kg up to 16.5 lb (7 kgs), for wet cautions of the street with one reflective collar

36 inches (90 cm), 1 kg up to 16.5 lb (7 kgs), for all usage on all roads with two reflective stripes

In Europe Countries, 3 sizes of traffic cone sizes as following:

350 mm, base size 230 x 230 mm,with 1 white print

500 mm, base size 290 x 290 mm,with 2 white prints

750 mm, base size 400 x 400 mm,with 2 white prints

How Is A Traffic Cone Produced?

The traffic cone production has several steps as follows:

Material: the raw materials are typically PVC (Polyvinyl Chloride) or LDPE (Low-Density Polyethylene), or rubber, prepared in granular or rubber sheet form.

Molding: the mold is made of steel with cone shape hollow, the raw material is heated and injected into cavity.

Cooling and Forming: Once the liquid materials are injected into the molds, then cool and solidify with air or water to make its temperature down.

Demold: after the liquid material is formed, the traffic cone will be demolded from the cavity by machine.

Edge Trimming: the edge of the traffic cone is rough, and you need to shape the edge with a knife to keep it smooth.

Inspection: pay more attention to checking and inspecting each cone before packing and taking a record.

Packaging: normally, traffic cones are packed by pallets with film and belt fixing and labeling.

What Can Traffic Cones Used For?

-

Road Construction Site: road cones are placed in the middle of roads, dangerous areas and road construction areas, etc., and around places that need to temporarily separate traffic, guide traffic, guide vehicles to bypass dangerous sections, and protect facilities and personnel on the construction site or other appropriate places.

-

Working Zone: safety cones are playing an important role in the public area of the project in protecting workers and the vehicles and pedestrians passing by. Under assistance of safety flags usage,the warning of safety will be much more visible and safe.

-

Traffic Direction: when there's a traffic accident on the street, it's very common to see traffic cones being used. They're used to indicate a separated path for the vehicles or pedestrians trapped in the accident, keeping the traffic flowing smoothly.

-

Road Lane: another function of traffic cones is to facilitate temporary detours. If a road is temporarily blocked, we need to redirect traffic to ensure vehicles can pass smoothly.

-

Pedestrian Walkways: cones for pedestrian walkways usually have message and symbol printed on reflective collar.

-

Accidents & Emergencies Sites: traffic cones are very common at the scenes of traffic accidents and emergencies. They are used to indicate and warn vehicles or pedestrians to pay attention to safe passage.

-

Highways & Freeways: traffic cones are widely applied in highways and freeways to indicate construction zones, lane closures, and some danger scenes for alerting drivers changing traffic patterns and making safe on the road.

-

Hospital: you can see traffic cones in lines in first aid entrance of hospitals and parking lots.

-

School: school door entrance application

-

Bank: bank entrance application

-

Parking Lots: isolate car space, lane closure, etc.

Types of Traffic Cone

There are many types of traffic cones,according to different classification standards, we can divide them into many types, such as by material, national standard,function, manufacturing process method,application, size, color and weight. Now I introduce each type one by one for you to learn more about traffic cones.

Material

-

PE Traffic Cone, the cone is made of LDPE (Low-Density Polyethylene) and produced by blowing mold.

-

PVC Traffic Cone, the cone is made of PVC (Polyvinyl Chloride) and manufactured by injection mold.

-

Rubber Traffic, the cone is made of recycled rubber and manufactured by rubber extrusion mold.

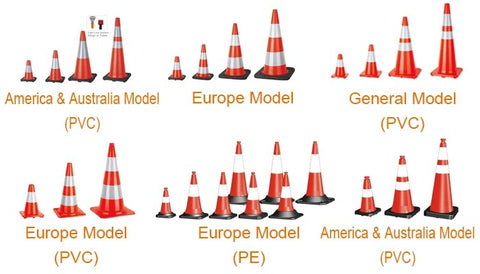

National Standard

-

US Traffic Cone, follow and meet US MUTCD Regulations

-

Europe Traffic Cone, complies with BS EN 13422 & Rohs

-

Australia Traffic Cone, complies with Australian Standard: AS 1742.3, Section 3.9.1

-

Italian Traffic Cone, complies with EN 13422:2020

Function

-

Reflective Traffic Cone, with high visible reflective collar, keep drivers safe.

-

LED Traffic Cone, with LED illuminating on top of cone or around cone body.

-

Collapsible Traffic Cone, pop-up cone, portable and fit for car safety kit.

Manufacturing Process Methods

The traffic cones are produced using three different manufacturing processes, which are: flow molded,injection molded,blowing molded and rubber extrusion.

-

Flow molded cone: flow molded is one type of processing especially for traffic cone manufacturing. It’s not flexible,precise and can not bounce back quickly as the injection molded traffic cone. The traffic cone is only produced in one piece.

-

Injection molded cone: the injection molded processing is the best choice for manufacturing high quality traffic cones, it’s made of durable recycled PVC material in two-pieces by black heavy base interlocked. Compared to flow molded traffic cones, it’s thick,heavy, flexible, can withstand any bad weather condition, and bounces back quickly.

-

Blowing molded cone: it's also called PE cone, as the cone body is produced by blowing mold processing. Blow molding, also known as hollow blow molding, is a method where plastic pellets are heated and melted before being injected into a mold. Utilizing air pressure, the plastic is blown to form cavities, and ultimately cooled and solidified into shape. This process is primarily suitable for plastics such as polyethylene, polyvinyl chloride, polypropylene, and polyester. Blowing molded cones consist of PE cone body and rubber base.

-

Rubber extrusion traffic cone: the rubber cone is completely made of recycled rubber and manufactured by traditional rubber extrusion molding, it’s heavyweight, soft, and UV-free, so the rubber cone has properties of stability, durability, and flexibility.

Application

-

Road Cone: it is used on the road as a barrier warning, such as fixed-point inspections by traffic police.

-

Parking Cone: it is widely used on parking lots.

- Obstacles Course Cone: it is used for training courses.

- Metro Cone: it is used in streets.

- Construction Cone: widely used on construction sites for warning.

Size

Traffic cones varies in many sizes, there are listed as below:Mini Traffic Cone, as the traffic cone model, is placed in the showing room.

1. Small Traffic Cone, from 4” to 6”, all called small cones.

2. Big Traffic Cone,means heavy duty weight cone, used for airport traffic control

3. 5” Traffic Cone, used in track and field competitions, events,obstacle courses and sports meetings.

4. 6” Traffic Cone, used in track and field competitions, events,obstacle courses and sports meetings.

5. 12” Traffic Cone, used in parking lots and working areas indoor and outdoor.

6. 18” Traffic Cone, used in streets for working areas as metro cones or events isolated.

7. 28” Traffic Cone, widely used for highway and freeway with high-vis reflective collar.

8. 36” Traffic Cone,also used for highway and freeway in good visibility reflective tape.

Weight

Cone weight has many different divisions, and different countries have different weight standards.

- Light Traffic Cone

- Heavy Duty Traffic Cone

Flow Molded Traffic Cone VS Injection Molded Traffic Cone

Mold Cost: the flow molded tooling cost is lower than injection mold for the traffic cone manufacturing process.

Price: flow molded traffic cones are cheaper than injection molded traffic cones.

Cone Material: flow molded traffic cone is produced by PVC in one piece completely, injection molded traffic cone is produced by PVC cone body and rubber base for interlocking together.

Cone Weight: injection molded traffic cone is heavier than flow molded cone due to interlocking base weight.

Stability: injection molded traffic cone with heavy base weight, absolutely has good stability compared to flow molded cone.

Production Efficiency: injection molded traffic cone production efficiency is better than flow molded cone.

What are the differences between plastic cones and rubber cones?

Plastic traffic cones and rubber traffic cones each have their own advantages and disadvantages in usage. Below, I will briefly introduce their characteristics.

Rubber traffic cones are made of vulcanized rubber, which possesses softness, wear resistance, good stability, and weather resistance. However, its disadvantage lies in its surface not being smooth enough, lacking a glossy and bright appearance, and generally being available in limited colors, with black being the mainstream color, though red and yellow are also possible.

Plastic traffic cones, primarily made of PVC or PE, have the advantages of being lightweight, convenient, and having bright colors with a smooth surface. Their disadvantage is their poor weather resistance, especially in low temperatures and UV resistance, which is inferior to rubber, resulting in a shorter lifespan compared to rubber cones.

Given the above descriptions, both plastic and rubber road cones have their pros and cons. The information provided aims to enhance your understanding of traffic cones. Therefore, when selecting traffic cones for your projects, be sure to choose according to your specific needs. We will continue to provide more knowledge about cones in the future.

15 Benefits Of Traffic Cone

- High visibility: traffic cones are typically bright orange or red in color, often accompanied by highly reflective strips. When car headlights shine on these reflective strips, they emit dazzling light, alerting individuals to their presence.

- Flexibility: traffic cones are manufactured using PVC or rubber materials, providing them with good flexibility and elasticity. When run over by vehicle tires, they quickly rebound back to their original shape.

- UV resistance: the raw materials of road cones include UV-resistant components, giving them excellent UV resistance and thereby increasing their lifespan.

- Sturdy: traffic cones are stable and withstand compactness.

- Cost-Saved: the material cost of plastic and rubber is very low, coupled with the fast efficiency of injection molding production technology, resulting in very low prices.

- Maintenance and Storage: road cones are hollow inside, allowing them to be stacked and nested, saving a lot of space for convenient storage and transportation.

- Warning of Construction Workzone: the site working areas need reflective high-visibility fluorescent traffic cones prior to safety for passing by vehicles and pedestrians.

- Direction Traffic: it's well known that the cone guides the traffic flow, this is traffic cone’s most important application.

- Marking Lane Closure: it's necessary to mark the lane closure for safety reasons in construction site working areas.

- Creating Detours: it's in wide application for road maintenance and upkeep.

- Marking Pedestrian Walkways: isolated the construction site working areas for pedestrians' safety.

- Marking Parking Spaces: stop others to occupy the personal parking space.

- Marking Off-limited Areas: give a warning sign for off-limited areas and pay more attention to the safety for drivers and people.

- Marking Temporary Accidents & Emergencies Sites: it's extremely necessary to place cones in accidents and emergencies sites for safety reasons.

- Marking Highways & Freeways: in the US,it's a must to put 28” traffic cones or taller cones in the highway and freeway,also the cones must be fitted with reflective tapes ton ensure high-visibility at night or low-visibility time. It will be better if cones are fitted with cone lights on the top of cones.

How To Choose Traffic Cones?

Traffic cones are one of the most widely used and safest safety facilities with the best cost-effectiveness on the market. Since their invention, they have a history of 80 years.

The choice of traffic cones often depends on the specific usage scenario. There are many types of traffic cones available, and we need to select the most suitable ones for you based on different requirements, materials, and weights to meet your needs.

Additional Tips for Placing Traffic Cones

The traffic cones are widely used for road construction sites, working zones, traffic crossings, road lanes, pedestrian walkways, accident & emergency sites, and parking lots. Before placing cones, you need to choose the flat surface of ground to keep the cone stable. Secondly, the cones need to be fitted with reflective collars. Lastly, often patrol and check if the traffic cones are in the correct position.

Working Zone

The Importance of Cone Reflective Tapes

The reflective tape is a flexible retroreflective material mainly used to improve the visibility of traffic cones at night so that they can be safely and effectively visible under the headlights of approaching drivers. Reflective tapes have different grades for visibility as following:

- Advertising-grade reflective tape

- Engineering-grade reflective tape

- High Intensity grade reflective tape

- High-Intensity Prismatic reflective tape (HIP)

- Diamond-Grade reflective tape

Related Products To Traffic Cones

- Cone Bars, expandable plastic bars are connected with cones in lines to make lanes in a row.

- Cone Plastic Chains, the plastic chains for traffic cones are aimed to direct traffic, mark construction working zones, or establish clear boundaries in various types of applications.

- LED Cone Lights, the cone top light is to improve the visibility at the nighttime for safety reasons.

- Cone Toppers, cone topper with retractable belt to connect many cones in a row to create a lane.

Conclusion

Traffic cones are a crucial and common safety facility in our traffic safety measures. With the development of society and advancements in technology, people are increasingly prioritizing safety awareness. Traffic cones are being applied to more fields and are being subdivided according to their purposes. They are becoming more versatile in functionality and performance, which allows for significant improvements. Let us provide valuable suggestions and enhancements for the development of traffic cones. In the near future, we will share more knowledge about traffic cones with our customers, enabling you to learn and benefit more.

FAQ

Is It Illegal To Take Traffic Cones?

Absolutely, take is stealing, if you do not buy, means the cone is not yours.Stealing traffic cones is an act of stealing public property and is illegal. The laws regarding this offense vary from country to country and region to region, and the legal consequences resulting from stealing traffic cones also differ. Generally speaking, stealing public property may result in fines, imprisonment, or other legal measures. Protecting and respecting public property is a fundamental principle that each of us must adhere to.

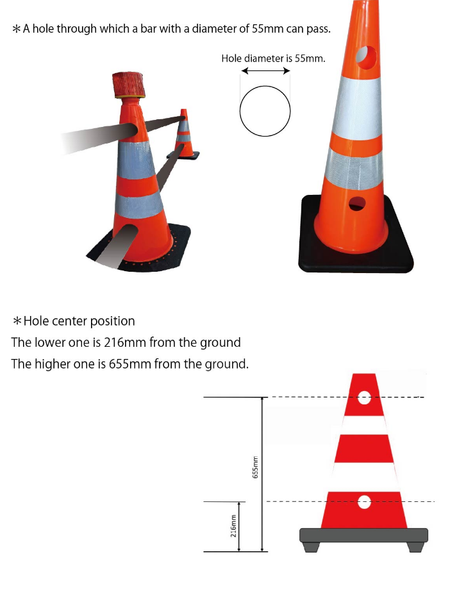

Why Do Traffic Cones With Holes Through?

Punching holes in the cones of traffic cones and then threading warning tape or bars through them is a DIY approach adopted by some customers with the aim of creating lanes. The advantage of this method is cost-saving and flexibility in adapting to different sites, thus meeting the needs of customers.